Our Products

At Reliance Weaving Mills Ltd., innovation meets craftsmanship to deliver an exceptional range of yarns sourced from premium cotton origins like Pakistan and CF Cotton. Whether it’s polyester/cotton blends, 100% cotton, or specialty yarns like Mélange and Slub, our products are designed for versatility and durability. From eco-conscious fibers like Tencel and Bamboo to certified yarns meeting GOTS, BCI, and GRS standards, we prioritize quality and sustainability. Trusted by industries ranging from fashion to agriculture, we proudly export our yarns under the renowned White Mountain brand, ensuring our excellence is recognized worldwide.

Our Product Range

Unit 3 Products

1. Mélange Yarn

Blending different fibers to create a vibrant multicolored effect, Mélange yarns add texture and visual interest to knitted garments. Ideal for fashion pieces like sweaters, scarves, and casual wear, these yarns offer subtle color variations, giving fabrics a unique appearance.

Count Range: Ne 10/1 to Ne 40/1

2. 100% Cotton Yarns

Soft, breathable, and versatile, 100% Cotton yarns are a staple in both knitting and weaving. Perfect for creating lightweight, comfortable clothing, these yarns are widely used in everyday wear, home textiles, and more.

Count Range: Ne 10/1 to 40/1

3. PC/CVC Yarns

Blending polyester with cotton, PC/CVC yarns combine the comfort of cotton with the durability of polyester. These yarn are resistant to fading, shrinking, and easy to care for, making them an excellent choice for garments like shirts, trousers, and hoodies.

Count Range: Ne 8/1 to Ne 16/1

4. Knitting Yarns

Crafted from a mix of fibers, including cotton and synthetics, Knitting yarns offer a balance of softness and durability. Whether for lightweight clothing, active wear, or casual garments, these yarns excel in a variety of knitting applications.

Count Range: Ne 24/1 Up to Ne 40/1

5. Fancy Yarns

Fancy yarns like Injection, Chain, Draw Blends, and tri-blends (cotton, polyester, and viscose) are used to create decorative and textured fabrics. These include slub yarns, which have irregularities in thickness, and injection yarns, which create unique patterns in the final product. They are often used in high-end fashion to add creativity and flair to garments.

6. Special Yarns & Optical Bright Yarns

Featuring special effects like PP Grey, PP Charcoal, PV heather grey, Viscose, and optical brighteners, these yarns are designed to create eye-catching designs. Perfect for fashion apparel and home textiles, they add visual appeal and enhance fabric brightness.

7. Blended Yarns with Special Fibers

Blended with eco-friendly fibers such as Tencel, Bamboo, Linen, and Viscose, these yarns offer moisture-wicking, biodegradable, and breathable properties. Ideal for sustainable fashion, they are crafted to support innovative fabric production with natural benefits. These yarns are commonly used for producing towels, socks, bed sheets, and other items with different fiber compositions.

Count Range: Ne 10/1 up to Ne 40/1 (Carded)

Unit 4 & 6 Products

1. Stretch Yarn

Offering elasticity and flexibility, Stretch yarns are used in garments requiring high stretch, such as activewear and leggings. These yarns are made with fibers like Spandex and Lycra, ensuring comfort and performance in stretchable fabrics.

Count Range: Ne 7/1 up to Ne 20/1 (with 40D & 70D)

2. Plied Yarns & Optical Bright Yarns

These advanced specialty yarns enhance durability and aesthetics with their soft and hard twists. Crafted for high-quality Towels and fabrics, these yarns also include zero twist with 80/1 PVA, combed, and carded options, along with bleached yarns, all designed to cater the towel sector having a classic finish and high end towel products.

Count Range Plied Yarns: Ne 20/2 to Ne 24/2

Count Range Zero Twist Yarns: Ne 10/1 Zero Twist Up to 20/1 Zero Twist (All twisted with 80/1 PVA having Melting temperature 90° C)

3. Compact Yarns

With their tightly twisted structure, Compact yarns offer a smooth, fuzz-free texture, making them perfect for high-end fabric production. These yarns provide a clean, refined appearance for woven and knitted textiles.

Count Range: Ne 16/1 to Ne 40/1

4. Slub & Siro Slub Yarns

Slub & Siro Slub yarns introduce artistic texture into fabrics, with their irregular thickness creating a distinctive look. These yarns are favored for decorative and fashion applications, adding character and uniqueness to garments.

Count Range: Ne 7/1 to Ne 14/1

5. Plain Yarns

Offering a consistent, smooth texture, Plain yarns are versatile and widely used in a range of textile applications. These yarns are perfect for creating durable, high-quality fabrics for everyday clothing and home textiles.

Count Range: Ne 7/1 to Ne 30/1, Ne 12/1 to Ne 40/1

6. Plain & Siro Yarns

Combining the simplicity of Plain yarns with the advanced spinning technique of Siro, these yarns offer superior strength, smoothness, and a reduced likelihood of pilling. They are ideal for producing fabrics with excellent drape and durability for DENIM products.

Count Range: Ne 7/1 to Ne 14/1

Certifications

We pride ourselves on the quality and sustainability of our products. Our yarns are certified by various global standards, including:

GOTS (Global Organic Textile Standard)

OCS (Organic Content Standard)

RCS (Recycled Claim Standard)

GRS (Global Recycled Standard)

PRIMARK

CMiA (Cotton Made in Africa)

BCI (Better Cotton Initiative)

INDITEX

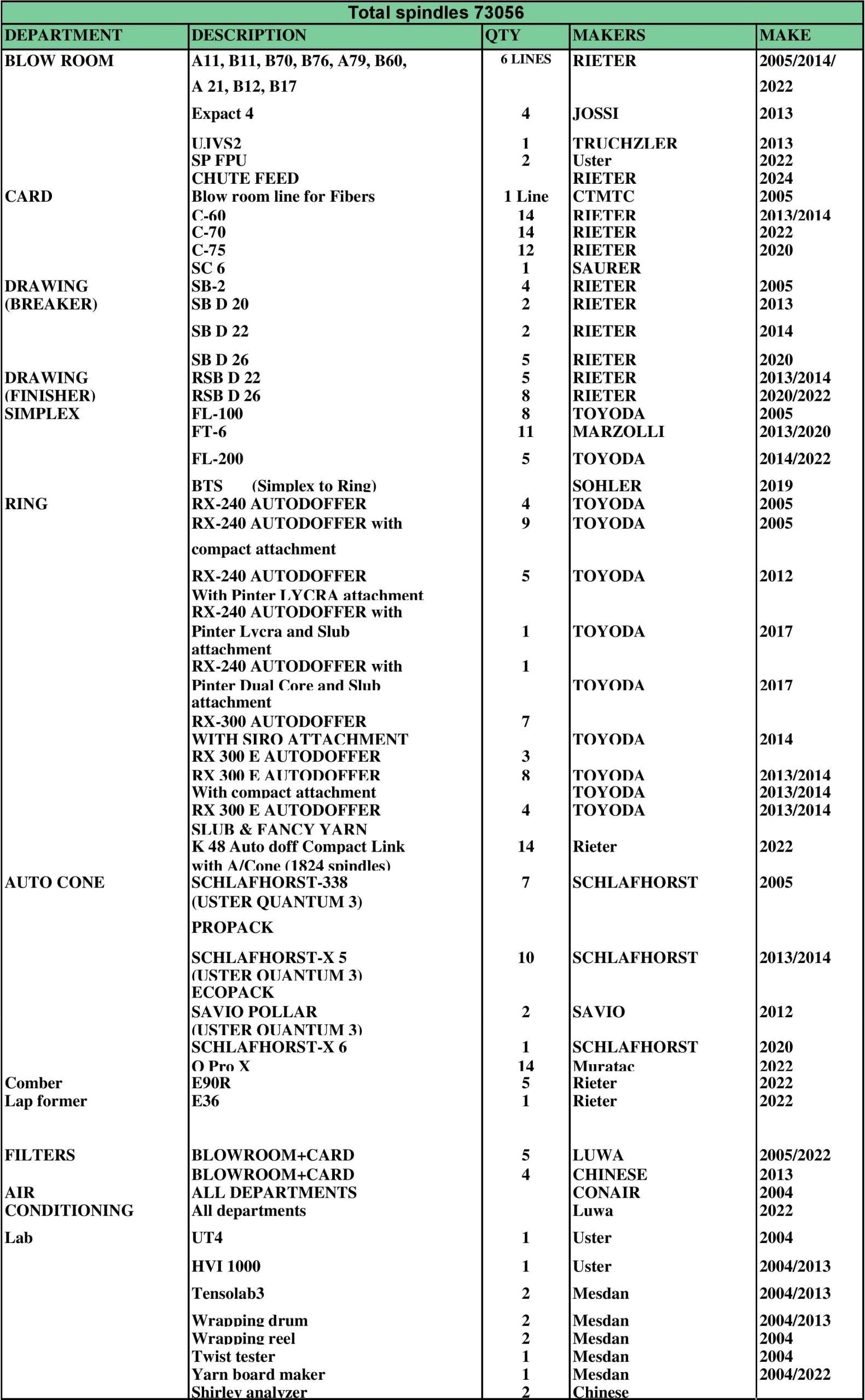

Our Machinery

The spinning operations at Reliance Weaving Mills are supported by a diverse range of modern machinery, ensuring optimal efficiency and quality in textile production. These units feature advanced equipment across various departments, including blow rooms, carding, drawing, combers, simplex, and ring spinning. The machines come from reputable manufacturers such as Rieter, Marzoli, and Toyoda. This extensive and technologically advanced setup facilitates a seamless production process, enhancing the overall output and quality of the textiles produced at the facility. The integration of preventive maintenance processes ensures the machinery operates at peak performance, minimizing downtime and extending the lifespan of the equipment.